Automation of the apparel sewing industry progressed dramatically in the 20th century. Technological innovations in machinery, synthetic fibers, logistics, and globalization of the industry required radical changes. Cotton and wool were joined by synthetic fibers such as rayon, nylon, acetate, acrylic, metal, polyester and spandex. As the industry grew and productivity became more important than ever, automation took a dramatic change.

Different applications required different stitches such as the chainstitch, lockstitch, overlock, coverstitch and zigzag stitch. The development of new sewing equipment became specialized, machines needed automation in the fast paced environment and ergonomic advancements for the operators. Sewing machinery became more complex by performing multiple task, for example, producing a sleeve for a t-shirt from a stack of precut parts could simply be done by placing a part on the conveyor, the sleeve is hemmed, folded in half, closed with a backlatch and stacked for the next process of attaching to the t-shirt body.

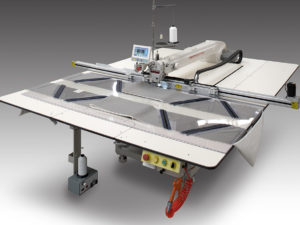

Atlanta Attachment Company specializes in the development of automated sewing equipment for the sewn products industry. The apparel line of equipment includes sewing machines for tee shirts, placket shirts, sweatshirts, sweatpants and shorts, uniforms, and for many other products such as blouses, ball caps, jackets, underwear, pajamas, jeans, overalls and aprons. The workstations are used for hemming, seaming, taping cutting, applying sleeves, cuffs, collars, elastic waistbands, pockets, ruffles and other required functions for the creation and assembly of apparel. AAC’s Engineering department is constantly updating equipment, developing new and improved models and working with customers to design and develop custom automated sewing equipment for specific applications.

See below for our apparel automation machines. Click on model number or image thumbnail to go to that model’s product page.

Note: Images on the pages contained on this website may include options. Please contact your sales representative for details on equipment you may be interested in.

-

1100

Automatic Panel Serger

-

1278-6

Automatic Rib Knit Bottom Band Setting Station

-

1278-8

Automatic Coverstitch Bottom Hemmer

-

1353LFHL

Large Label Tacker for Apparel Production

-

1536A

Automatic Elastic Leg Hemming Station

-

1996

Automatic Collar and Waistband Workstation

-

211E

Automatic Two-Needle Hemmer for Sleeves

-

211M

Semi-Automatic Two-Needle Sleeve Hemmer

-

213E

Automatic Two Needle Hemmer for Sleeves and Shirt Bottoms

-

217

Automatic Blindstitch Sleeve Hemmer for Shirt Bodies

-

350-50

Automatic Clean Finish Elastic Waistband Workstation with Fold-in-Half Stacker

-

3800P

Automatic Set-in Pocket Workstation

-

411F

Automatic Hemmer/Seamer

-

981

Automatic Placket Fusing, Cutting and Stacking

-

982

Automatic Placket Setting Workstation

-

996

Automatic Tee Shirt & Turtleneck Collar Workstation

-

997

Automatic Cuff Machine

-

AP23

Automatic Rib Knit Cuff Setting Station

-

AP24

Automatic Rib Knit Leg CuffSetting Station