Images may include options

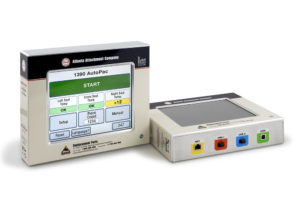

Automatic Rib Knit Bottom Band Setting Station

Shirt and band may be tubular or with side seams

- DC electronic motor & microprocessor controls

- Tandem operation

- Reduces ergonomic risk

- Minimizes fabric waste

- Uniform gathering

- Dual electronic active edge guiding system

- Automatic stack

- Increased production

- Piece counter

An automatic workstation for sewing circular rib knit bottom bands on sweatshirts. This unit incorporates a cylinder arm overlock sewing head with vacuum thread trimmer, electronic controls, dual electronic active edge guiding system for band and body, and pneumatic expansion rollers with automatic stacker.

| Voltage (v/ph/hz) | 220v 1ph |

| Current (amps) | 6 |

| Air pressure (psi) | 90 |

| Air consumption (cfm) | 23 |

| Shipping weight (lbs) | 890 |

| Shipping dimensions (w/l/h, inch) | 60x54x60 |

180 – 225 dozen bottom bands per 8 hour shift. (based on a tandem setup)

Depending on material and size of parts

The operator folds the circular rib knit piece in half to form a band and places it over the expansion guide rollers. The rollers automatically expand for loading the body. The body is loaded over the rollers and band and a touch of the start sensor expands the rollers to sew position and indexes the parts under the presser foot and sew cycle begins. The operator is free to load a second machine. When the finished seam is sensed the parts are oversewn a predetermined distance, thread chain is cut, and the part is automatically stacked.

Yamato AZ8403

Pegasus

Juki

Union Special