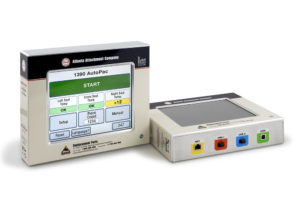

Images may include options

Automatic Hemmer/Seamer

An electronically controlled automatic workstation consisting of a conveyorized hemming system, fold-in-half station, a closing station with automatic backlatch and a programmable indexing stacker.

- Patented Serial Bus Control System

- DC electronic motor

- Combines hemming and closing operation w/auto backlatch

- Sews 100% cotton thread max RPM

- Plain hem or imitation collarette style (patented)

- “No tool” adjustments by operator

- Auto indexing stacker

- Computerized soft touch control system

- Adjustable transfer station for closing straight or contour seams

- Unique automatic fold-in-half system allows sleeves to be overlapped during sew cycle, increasing production

- Self-contained waste removal system

- Operator and technician friendly for easy adjustments and maintenance

| Voltage (v/ph/hz) | 220v 1ph |

| Current (amps) | 15 |

| Air pressure (psi) | 90 |

| Air consumption (cfm) | 25 |

| Shipping weight (lbs) | 1950 |

| Shipping dimensions (w/l/h, inch) | 106 x 65 x 67 |

1,120 hemmed & closed sleeves per hour

2211-EG1 – Active Edge Guide

311-5A – Top cover 3 needles

The operator places parts to an edge guide, initiates the sewing cycle and continues loading. The sleeves are automatically trimmed, folded, hemmed, folded in half, transported to closer, backlatched, closed and stacked. Stacker indexing is accomplished through programming of the number of sleeves in a bundle.