Images may include options

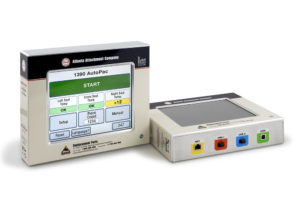

Automatic Cuff Machine

A fully automatic rib knit cuff workstation, utilizing a programmable microprocessor with touch screen for operator input.

- 30 Rib knit cuffs cut, folded, and counted per minute

- Tubular or with seams

- Select the language of your choice

- Fully automatic operation after loading

- Microprocessor controls

- Self-diagnostic software

The self-diagnostic software prompts the operator or technician to quickly identify a problem.

The model 997 requires two modules, model 997C Auto Circular Cuff Console and the optional model 997S Auto Seamer.

| Voltage (v/ph/hz) | 220v 1ph |

| Current (amps) | 5 |

| Air pressure (psi) | 90 |

| Air consumption (cfm) | 10 |

| Shipping weight (lbs) | 1200 |

| Shipping dimensions (w/l/h, inch) | 96 x 60 x 65 |

Approximately 1,800 cuffs per hour

Depending on material and size of parts.

997S – Auto Seamer

The rib knit cuff material may be tubular or pre-seamed utilizing the optional sewing module. After loading, the operation is fully automatic. This workstation may be programmable to produce a predetermined style or quantity of cuffs.