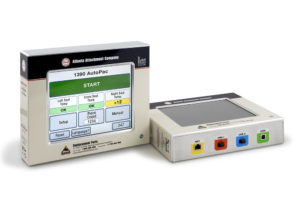

Images may include options

Automatic Coverstitch Bottom Hemmer

Shirts may be tubular or with side seams

- Patented Serial Bus Control System

- Shirt may be hemmed first or last operation

- Tandem operation

- Automatic size control

- Perfectly aligned oversew

- Electronic active edge guiding system

- 100% cotton thread max RPM

A tubular or side-seamed body is loaded over the expansion rollers. When loaded, the rollers expand to the proper tension, indexes the shirt under the presser foot, and the sewing cycle is initiated. The operator is free to load a second station. The finished hem is sensed and perfectly oversewn (with stitch-condensing if desired). The threads are trimmed and the garment is automatically stacked.

| Voltage (v/ph/hz) | 220v 1ph |

| Current (amps) | 6 |

| Air pressure (psi) | 90 |

| Air consumption (cfm) | 23 |

| Shipping weight (lbs) | 1079 ea |

| Shipping dimensions (w/l/h, inch) | 60 x 54 x 60 ea |

Approximately 660 bottom hems per hour, depending on material and size of parts. (based on tandem setup)

| Part # | Description |

| 1278-8KIT24 | Mechanical Seam Detect |

| 1278-8KIT25 | Mechanical Seam Detect + Seam Flip, Pegasus |

| 1278-8KIT26 | Mechanical Seam Detect + Seam Flip, Yamato |

A tubular or side-seamed body is loaded over the expansion rollers. When loaded, the rollers expand to the proper tension, indexes the shirt under the presser foot, and the sewing cycle is initiated. The operator is free to load a second station. The finished hem is sensed and perfectly oversewn (with stitch-condensing if desired). The threads are trimmed and the garment is automatically stacked.