Images may include options

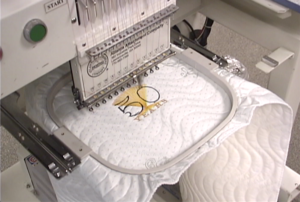

Automated multi-head Embroidery System for the Furniture Industry

Custom embroidery can add an elegant look to furniture surfaces. Selective use of logos or custom designs can make the furniture stand out. Utilizing multi-head embroidery systems can reduce the production time.

- Customized borders enhance brand recognition

- Borders may be personalized for each customer

- Raises price point, increasing profits as no outsourcing required

- Small quantities produced on demand

- Customer loyalty enhanced

- Multi-head design, high production, low cost

- Eliminates foreign mass-produced bedding competition

- Scan any logo and digitize in-house

- AAC offers complete training and logo digitizing service

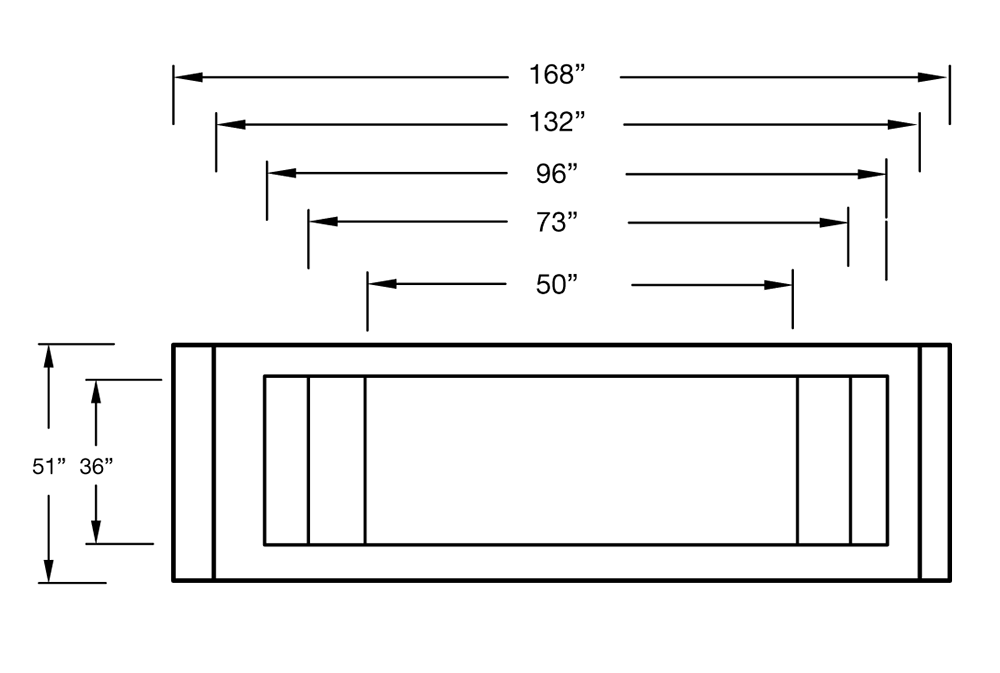

| E1501R | E1502R | E1204R | E1206R | E1208R | |

| Sewing Heads | 1 | 2 | 4 | 6 | 8 |

| Footprint | 50” x 36” | 73” x 36” | 96” x 36” | 132” x 51” | 168” x 51” |

| Max sewing speed (rpm) | 1000 | ||||

| Numbers of needles | 9 | ||||

| Embroidery field (mm) | 450 x 360 | ||||

| Factory preset speed | 800 | ||||

| Needle system | SNDBXK575 | ||||

| Weight of material | L-M | ||||

| Voltage (v/ph/hz) | 3-phase : 200/220/240/380/400/415/V 50Hz 60Hz | ||||

| 1- phase : 200/220/230/240V 50Hz 60Hz | |||||

| Power consumption | 310-420w | ||||

| Motor type | AC Servo motor x 1 / Motor servo AC x 1 | ||||

• Latest noise reductions developments help create a quiet and pleasant working environment for operators.

• Standard memory is 2,000,000 stitches and able to store a Max. of 200 designs.

• Scale your designs down to 50% or up to 200% in increments of 1%, and rotate in 1-degree increments.

• Continue to operate the machine after power failure during embroidery without missed production due to design displacement.

• Modify, insert or delete your embroidery design data stitch by stitch.

• Automatic color changes.

• Automatic Lubrication System