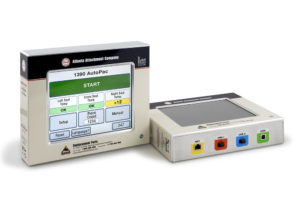

Images may include options

Automatic Short SleeveClosing Workstation

- Auto start

- Auto bundle return

- Auto backlatch

- Auto thread cutter

- DC electronic motor & microprocessor controls

- Electronic active edge guiding system

- Auto thread saver

- Auto piece counter

- Auto stacker

An electronically controlled sleeve closing station with automatic backlatch designed to close short sleeve tee shirt sleeves. This unit includes our exclusive electronic active edge guiding system, providing the capability to sew either straight or contoured seams.

| Voltage (v/ph/hz) | 220v 1ph |

| Current (amps) | 5 |

| Air pressure (psi) | 90 |

| Air consumption (cfm) | 12 |

| Shipping weight (lbs) | 1350 |

| Shipping dimensions (w/l/h, inch) | 60 x 60 x 65 |

Approximately 1,080 closed sleeves per hour, depending on material and size of parts.

The operator folds the sleeve and presents it to the presser foot. A photo cell senses the beginning edge, drops the presser foot and begins the sew cycle with an automatic backlatch. The electronic active edge guiding system controls the sleeve during sewing, while the operator prepares the next sleeve. When the seam is completed, the machine stops, the thread chain is cut and the sleeve is stacked automatically. Stacker selection is available for either single or double stack.

Most industrial overlock machines.