Images may include options

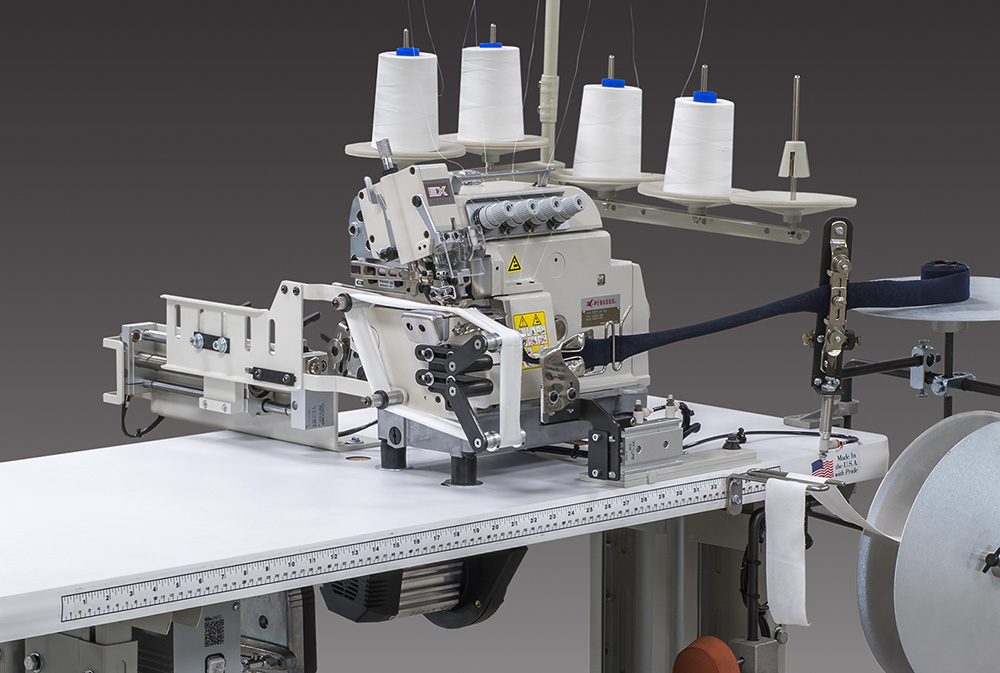

Circular Collar Setting and Taping

A pneumatically controlled set of rollers & taping folder designed to apply tape to a circular knit collar while the collar is being sewn to the shirt.

- Tape shoulder seam to shoulder seam only

- No production loss at collar setting

- Topstitch at final operation allows shirt to be finished, folded, warehoused and labeled as sold

- Pneumatic operation

- Simple in-house installation

A pneumatically controlled set of rollers & taping folder designed to apply tape to a circular knit collar while the collar is being sewn to the shirt.

Note: The 273-37S operates the same as the 273-37 except the rollers, while adjustable for size, do not expand or retract pneumatically.

| Voltage (v/ph/hz) | 220v 1ph |

| Current (amps) | 5 |

| Air pressure (psi) | 90 |

| Air consumption (cfm) | 2 |

Pieces per hour, depending on material and size of parts: 165 – 175

Heel the treadle to raise the presser foot – load the circular collar over the rollers and under the foot – load the shirt over the rollers and under the foot. A touch of the knee switch shifts the folder to the left and expands the rollers bringing the tape in line with the presser foot. Drop the foot and sew – approximately 1” from the shoulder seam the folder is shifted to the right by depressing the knee switch – continuation of sew will allow the tape to be cut by the edge trimming knife – this produces a neat rounded finish on the tape. The tape may be inserted or retracted at any point in the operation.

Most industrial cylinder arm machines.