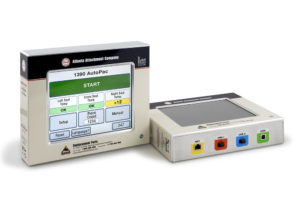

Images may include options

Automatic Two Needle Hemmer for Sleeves and Shirt Bottoms

Sleeves & Bottoms

- Patented Serial Bus Control System

- DC electronic motor & controls

- Reliable edge trimmer

- Fold-in-half & stack or stack only

- Stacker & return conveyor for bottom hemming available

- Optional imitation cuff attachment (patented)

An electronically controlled workstation consisting of a conveyorized downturn hemming apparatus with two-or-three needle bottom and/or top coverstitch sewing head, electronic motor, automatic edge trim and cut apart, and self-contained waste disposal.

| Voltage (v/ph/hz) | 220v 1ph |

| Current (amps) | 5 |

| Air pressure (psi) | 90 |

| Air consumption (cfm) | 21 |

| Shipping weight (lbs) | 1700 |

| Shipping dimensions (w/l/h, inch) | 132 x 72 x 65 |

• Sleeves: Approximately 1,950 pieces per hour, depending on material and size of parts.

• Bottoms: Approximately 1,245 pieces per hour depending on material and size of parts.

- 2211-EG3 – Edge guiding system

- 2211PKIT01 – Pocketloading station

- 211-KIT01 – Thread handling

- 311-006B – Fold in half stacker

- 311-5A – Top cover 3 needles

The operator places parts to an edge guide and initiates sewing. The unit will continue sewing as long as parts are placed on the conveyor within a specific distance. The sew cycle will stop if the operator fails to position the next part.

Most industrial coverstitch machines