Images may include options

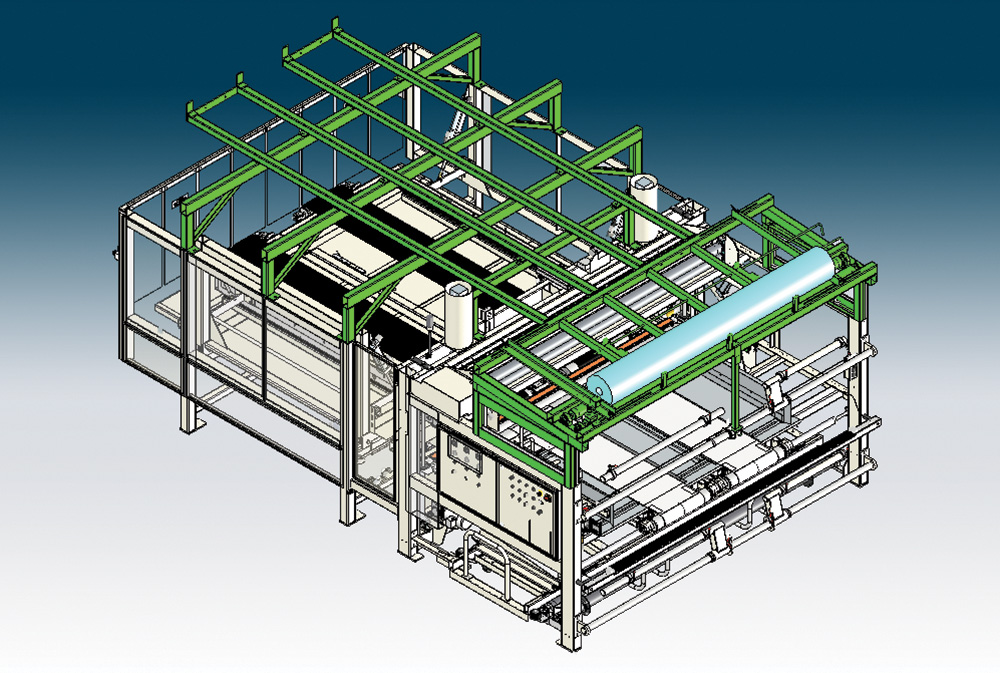

Latex and Foam Auto-Pac™

Designed Specifically for Stacks of Latex and Foam Panels

- Splice film with NO WASTE!

- Unique “no contact” photocell array adjusts side seals without distorting stack

- Serial Bus Control System for reliable operation

- Wraps one or multiple pieces of foam up to 21″ high

- Left and right seal bars adjust independently

- Extra wide conveyor belts

- Continuous heat seal bars are “double sealed” for strong seams

- Front seal bar for splicing rolls

- Optional hoist for loading film rolls

- Optional side compression ensures a tight wrap

- Optional pneumatic grippers remove and dispose of edge trim

| Max width of infeed (inch) | 85 |

| Min width of infeed (inch) | 72 |

| Max height under pressure roller (inch) | 21 |

| Roll capacity, top & bottom | 4 (12″ DIA) |

| Infeed/Outfeed conveyor height (inch) | 30 |

| Overall height | 102 |

| Overall height with hoist option (inch) | 144 |

| Max film width (inch) | 120 |

| Top film width: Top (inch) | 108 |

| Top film width: Bottom (inch) | 100 |

| Voltage (v/ph/hz) | 240V 3PH 60HZ |

| Current (amps) | 30 |

| Air consumption (cfm) | 35 |

| Air pressure (psi) | 80 |

| Machine weight (lbs) | 16,000 |

| Shipping weight (lbs) | 18,000 |

| Shipping dimensions (w/l/h, inch) | 75 x 144 x 81 92 x 144 x 104 |

3 Foam Stacks wrapped per min. (no compression)

2-3 Foam Stacks wrapped per min. (with compression)

1391106 – Multi-Roll Holder

• SAFE, rugged option for all AAC model 1390 Auto-Pac™ workstations

• Load with forklift, No lifting or climbing

• 16 roll capacity (up to 12″ diameter)

• Reduces downtime for Auto-Pac™ workstation

• Frees up storage space on manufacturing floor

• 1391593 – Side compression

• 1391332 – Trim removal kit

• 0411-1903 – Foot switch assembly

• 1390563 – Hoist system

• 1391277 – Full compression module