Images may include options

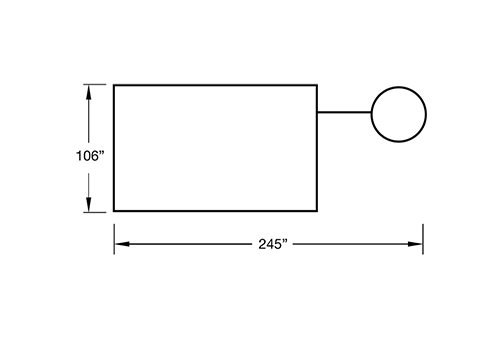

Class: 1313T

Pocket Spring Coiling Machine

- Spring coiling device for the production of pocketed springs

- Continuous or adjustable mode of operation for automatic cutting

- Fully automatic mode of operation

- Ease of changeover

- Heat treatment system withcooling station

- Fabric strip feed and folding device and spring upright positioner

- Ultrasonic welding unit

- Soundproof enclosure

- Optional automatic cutting device

| Wire gauge (inch) | .05-.08 |

| Operation mode | Continuous or adjustable for required coil count |

| Welding unit | Telsonic Ultrasonic system / Titanium Horns |

| Controls | 8 axis motion controller & 8 Brushless Servo Axis |

| Maximum wire reel weight (lbs) | 1984 |

| Spring diameter (mm) | 42-54 |

| Spring height (without fabric) (inch) | 5.1-8.3 |

| Spring height (with fabric) (inch) | 4-6.7 |

| Fabric rolls width (inch) | up to 31.5″ |

| Spring type | Barrell, cylindrical |

| Speed control | 3 x brushless servo motor |

| Main motor control | 1 x brushless servo motor |

| Unwinder motor power | 1.5Hp |

| Heat treatment control | Electronic switching |

| Air Pressure (PSI) | 90 |

| Air Volume (CFM) | 25 |

| Voltage Input Transformer (available taps) | (200V, 350V, 400V, 440V) 3PH |

| Voltage Output Transformer | 380V 3PH – 50/60HZ 30 AMP |

| Breaker Circuit (AMP) | 40 |

| Shipping weight (lbs) | 9524 |

70 springs per minute

| SWG (Standard wire ga.) | ||

|---|---|---|

| GUAGE | in. | MM |

| 13 | 0.092 | 2.337 |

| 13.75 | 0.083 | 2.108 |

| 14 | 0.080 | 2.032 |

| 15 | 0.072 | 1.829 |

| 16 | 0.064 | 1.626 |

| 17 | 0.056 | 1.422 |

| 18 | 0.048 | 1.219 |