Images may include options

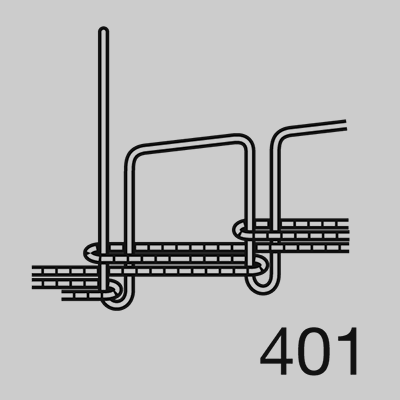

Double Serging & Gather Border

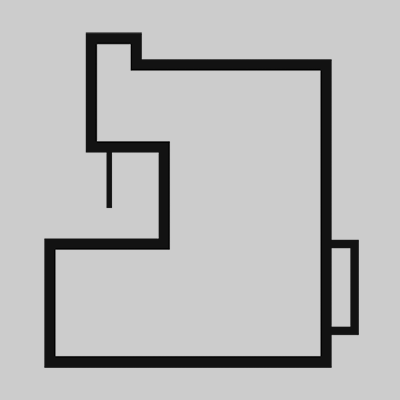

- Material capacity: 8.5″-18″

- Electronic DC Servo motors

- Electronic needle positioning on sew heads (no synchronizer required)

- Electronic thread break detection

- Variable tensioning of border material

- Servo drive variable speed puller with long-lasting urethane rollers

- Material out detection

- Foot pedal activation for splicing and servicing

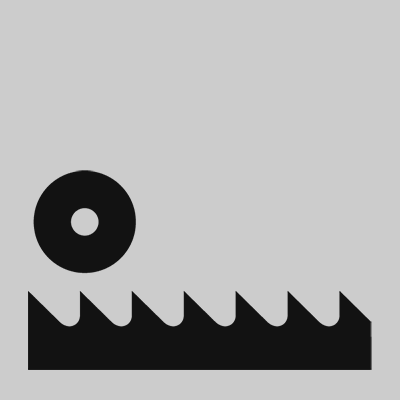

- Shearing values are electronically adjustable

- Short rolls or scrap border can be used

| Max sewing speed (rpm) | 4000 |

| Factory preset speed (rpm) | 4000 |

| Max stitch length (spi) | 4 |

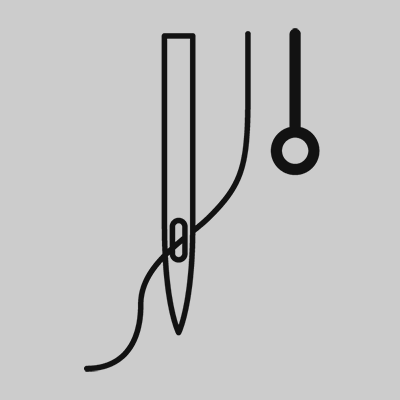

| Needle system | SN27140 |

| Needle size | 22/140 |

| Weight of material | MEDIUM |

| Max presser footlift (inch) | 7/32 |

| Voltage (v/ph/hz) | 220V 1PH 60HZ |

| Current (amps) | 10 |

| Motor type | DC SERVO |

| Air pressure (psi) | 80 |

| Air consumption (cfm) | 14 |

| Shipping weight (lbs) | 1200 |

| Shipping dimensions (w/l/h, inch) | 62 x 96 x 57 |

100 – 125 Feet per min. depending on material and shirring ratio, approx.

• 1961-650 – Yardage counter

• 1961-650A – Preset yardage counter

• 1961112 – Flange front assembly

The operator loads the border, backing, and ticking materials through the front tension assembly and uses the foot pedal to sew them through the sergers. Activating the puller lift switch opensthe puller, the border is inserted between the rollers and the switch closes the puller.

The operator places the cloth between the spindle rods on the winder and presses the start button. The unit automatically sergers the edges together while shirring the top ticking layer and will stop whenany of the materials run out.

The finished width of the goods being sewn can be adjusted by turning a crank and moving the left serger. A scale is provided which indicates the finished width of the goods being sewn.

Finished border is rolled up on the winder.