Images may include options

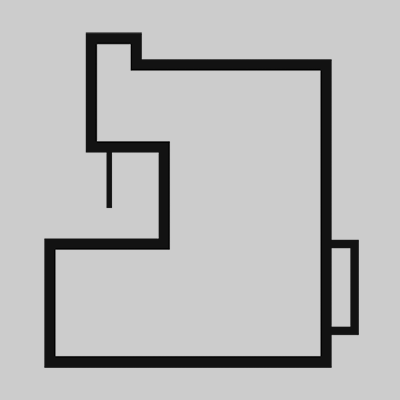

Automatic Sew & Miter Corner Workstation

Can be used with optional 1354-950, Thermo Label Printer

- Modular design

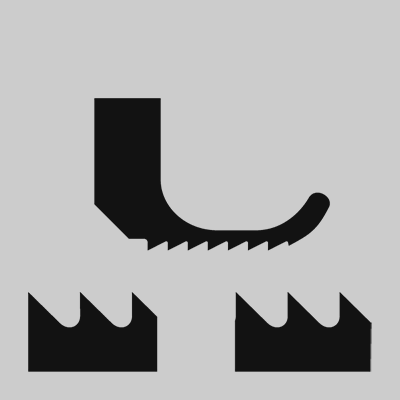

- Sew corner and cut miter

- Optional thermal label transfer

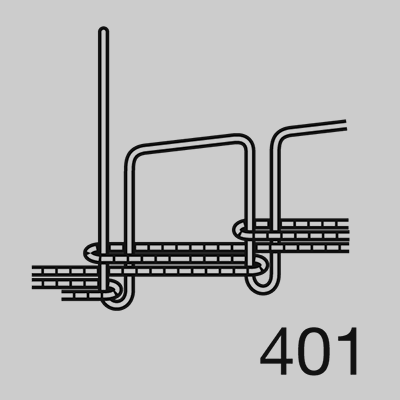

- Safety stitch automatically cuts and sews corner seams

- Patented Serial Bus Control System

- Automatic border splice and defect detection

- Heavy-duty safety stitch sewing head with automatic chain cutter

- Heavy-duty guillotine cutter with tempered blades

- Electronic thread break detectors

- Heavy-duty feeding module with urethane rollers

- Electronically stops when border material depleted

- Electronic servo drive motors

- Preset counter for multiple borders

| Max sewing speed (rpm) | 6,000 |

| Factory preset speed (rpm) | 3,000 |

| Max. stitch length(spl) | 5 |

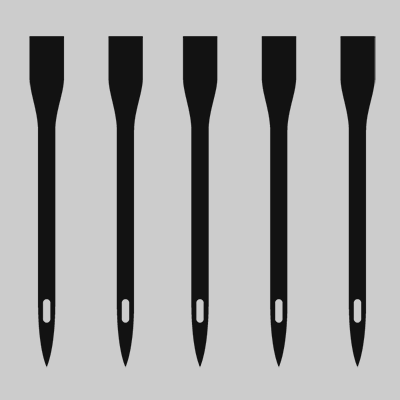

| Needle system | SNB27140 |

| Needle size | 140 |

| Weight of material | LIGHT/MEDIUM |

| Voltage (v/ph/hz) | 220V 1PH 60HZ |

| Current (amps) | 5 |

| Motor type | Efka DC |

| Air pressure (psi) | 80 |

| Air consumption (cfm) | 5 |

| Shipping weight (lbs) | 2250 |

| Shipping dimensions (w/l/h, inch) | 77 x 110 x 88 |

13-35 Queen borders per hour depending on pattern and width of border

- 1354-950 – Thermal label transfer machine

- 1325370 – Zipper & trim workstation

- 11352Q88 – Double needle, heavy duty, topstitch, border workstation

- 11351Q83 – Border Closer Workstation

33210 – Automatic sew & miter corner workstation