Images may include options

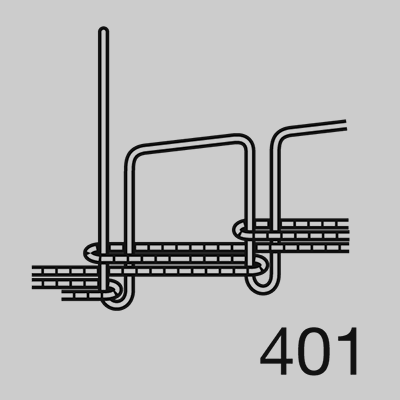

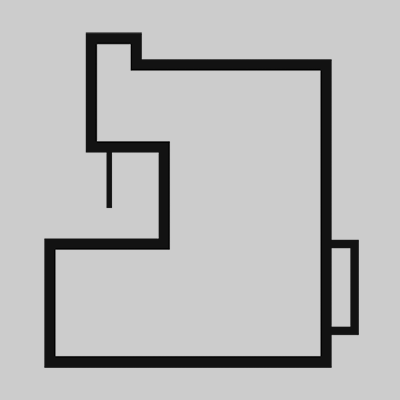

Semi-Automatic Panel Serging and Flanging with Belted Conveyor

- Powered conveyor table

- Corner turning arm with adjustable radius

- Automatic flange cutting and re-insert

- Auto stop at corners

- Auto unload feature

- Electronic thread break detection

- Reliable Serial Bus Control System

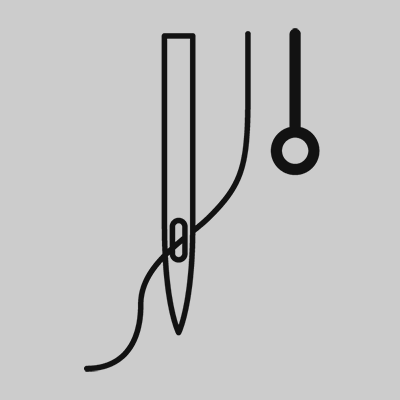

- Heavy-duty High-Lift five-thread safety stitch sewing head

- Electronic puller

| MAX SEWING SPEED (RPM) | 3500 | |

| Factory preset speed (rpm) | 3500 | |

| Max stitch length (spi) | 4 | |

| Needle distance (inch)1 | 1/4 + 3/4 | |

| Needle system | SBN149X7#140 | |

| Needle size | 140 | |

| Weight of material | MEDIUM / HEAVY | |

| Voltage (v/ph/hz) | 220V 1PH 50/60HZ | |

| Current (amps) | 15 | |

| Motor type | EFKA DC | |

| Air pressure (psi) | 80 | |

| Air consumption (cfm) | 20 | |

| Shipping weight (lbs) | 2500 | 1000 |

| Shipping dimensions (w/l/h, inch) | 192 x 91 x 45 | 72 x 65 x 72 |

60 panels per hour

11317C -Semi-Automatic Panel Serging and Flanging with Belted Conveyor