Images may include options

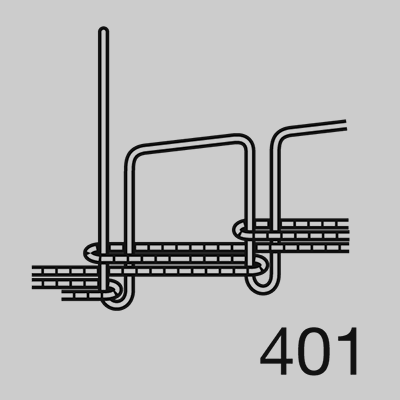

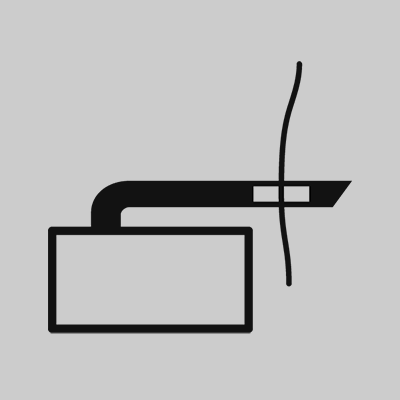

Automatic Tape Edge Workstation

- Simple conveyor design allows for easy belt replacement (approximately 1 hr.)

- Electronic needle positioning (no synchronizer)

- Rugged steel frame construction

- Patented Serial Bus Control System (Unconditionally guaranteed for 3 years)

- High lift (7/16″) walking presser foot feeding system

- AAC300UX6 sewing head

- AAC guarantees all expendable replacement parts will be shipped within 72 hours or they will be FREE*!

* Contact sales for the recommended spare parts list and the model workstations covered.

| Max sewing speed (rpm) | 3000 |

| Factory preset speed (rpm) | 2700 |

| Max stitch length (spi) | 4 |

| Needle system | SN62X5924 |

| Needle size | 24-180 |

| Weight of material | MEDIUM / HEAVY |

| Max presser footllift (inch) | 7/16 |

| Voltage (v/ph/hz) | 220V 1PH 50/60HZ |

| Current (amps) | 15 |

| Motor type | EFKA DC |

| Air pressure (psi) | 80 |

| Air consumption (cfm) | 5 |

| Shipping weight (lbs) | 3500 |

| Shipping dimensions (w/l/h, inch) | 180″ x 98″ x 96″ |

20 Pieces Per Hour (2 tape edges)

Operator platform automatically raises and lowers with sewing head to maintain operator’s ergonomically correct height.

The speed of the sewing head can be independently adjusted by the operator for synchronizing head and belt (no more tugging).

Corner sewing speed is adjustable by operator. The mattress always rotates correctly without the operator having to tug to keep the mattress in the binder.

After tape edging the first seam, the operator touches the screen, the mattress is automatically pushed clear of the head and the mattress is flipped and pushed back to the operator.

Automatic mattress flipping eliminates operator handling. Auto flipping mechanism can be installed on either end of workstation.

After flip, mattress is automatically relocated to the sewing head. No tugging by the operator.